Harwood Sugar Mill, NSW Australia YouTube

#0183;#32;A look at the Harwood Sugar Mill, on the north coast of New South Wales, Australia. Seen are the two steam engines that drive the cane crushing, plus a look

WhatsApp)

WhatsApp)

#0183;#32;A look at the Harwood Sugar Mill, on the north coast of New South Wales, Australia. Seen are the two steam engines that drive the cane crushing, plus a look

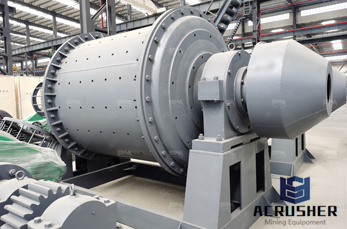

Used Mill Equipment. There are many different names that are used to describe particle size reduction: milling, grinding, granulating, comminuting, etc. Milling systems can size reduce wet or dry powders. Their are variable speed drives that permit low speed screening and

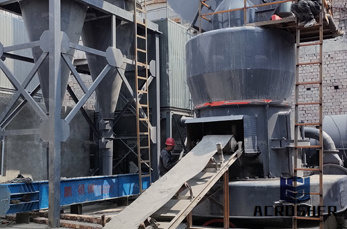

Milling Section. Shrijee is fully equipped to supply all cane handling equipment / preparation equipment such as cane unloader, feeding table, cane kicker, cane cutter, fibrizer, chopper and cane carrier with variable frequency drive system. The sugar cane milling tandem can be supplied with 3 roller, 5 roller, 6 roller mill with plantery gear drive systems.

23 #0183;#32;Over 4000 sugar cane farms produce 3235 million tonnes of sugar cane each year, from

Inkerman sugar mill in Australia A sugar cane mill is a factory that processes sugar cane to produce raw or white sugar . The term is also used to refer to the equipment that crushes the sticks of sugar cane to extract the juice.

Turnkey Sugar Plant (EPC) Established in 1976, Shrijee is one of the worlds leading manufacturers and suppliers of sugar plant and machinery. Since Shrijee''s inception, the objective of manufacturing improved continuous type of sugar industry equipment was pursued. We have constantly been evolving newer designs, diversifying its activities to meet the needs of changing times and expanding its

australia sugar mill equipment . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen. Raw Complex Gold Ore Processing Machine.

equipment. Mills operate in two distinct modes, crushing and noncrushing, both of which introduce a range of specific and general hazards to persons conducting a business or undertaking (PCBU), workers and others. In essence, a sugar mill can be broken into the following processes (see Figure 2 for a diagram that shows the sugar milling

Sugar is Australia''s second largest export crop, after wheat, with a total annual revenue of almost 2 billion. Around 95% of sugar produced in Australia is grown in QLD, with the remainder in northern NSW. Australia exports 80%85% of its raw sugar to buyers overseas, making it the second largest raw sugar exporter in the world.

We''re Australia''s second largest sugar milling company, with over 140 years'' experience and an annual turnover in excess of 300 million. We have three operating milling sites at Farleigh, Marian and Racecourse and hold a 25 per cent interest in Sugar Australia Joint Venture; Sugar Australia, and New Zealand Sugar Company.. Our products include raw and refined sugar, molasses and renewable

Equipment carries a large inventory of unused and used sugar mill equipment. Request a sugar mill equipment quote online.

Other equipment we provide for the sugar industry includes energyefficient decanter centrifuges and rotary lobe pumps. Downloads. Sugar 1869 kB. M30 heat exchanger boosts evaporation capacity at Australian sugar mill . In 1992 Mulgrave Central Mill installed

Turnkey Sugar Plant (EPC) Established in 1976, Shrijee is one of the worlds leading manufacturers and suppliers of sugar plant and machinery.. Since Shrijee''s inception, the objective of manufacturing improved continuous type of sugar industry equipment was pursued. We have constantly been evolving newer designs, diversifying its activities to meet the needs of changing times and expanding

Australias Leading Sugar Business. Since 1855, Sugar Australia has been the leading producer of sugar to the Australian Food and Beverage industry. Backed by a strong manufacturing and supply chain capability, we aim to deliver everyday excellence to our customers across Australia and throughout the Asian region.

The NQEA circular bin is well proven in over 27 fully automatic installations worldwide, 24 of which are in Australia, 2 in Fiji and 1 to Jamaica. These units are a key component for providing economical cogeneration at many sugar mills. Continuous Vacuum Pan. Continuous A Grade Fugal. Bagasse Bin Interior.

In the past, only conventional pin mills were used. Today, considerably higher throughputs can be obtained using socalled blast mills. The usual powdered sugar finenesses of 80 95% lt; 100 #181;m can be obtained, as well as considerably higher finenesses.

Major equipment includes Milling equipment, Steam Boiler, Juice Heaters, Clarifier Tanks, Vacuum Pumps, Crystallizers, Centrif... Sugar Mill. Rated 2,000 tons of cane per 24 hours. Used Sugar Mill. Rated 2,000 tons of cane per 24 hours. Maximum

Equipment has over a 75year reputation in Sugar Mill Equipment expertise. Use our Sugar Mill Equipment resource center to help solve your equipment needs.

equipment. This new edition of the Laboratory Manual has, as far as possible, Australia. We also gratefully, Director 1st February, 1970 Bureau of Sugar Experiment Stations, Brisbane . PREFACE TO FIRST EDITION The Division of Sugar Mill Technology was created in 1929. One of the early duties of

Australia Sugar Mill Equipment Alloys Staff are located in the heart of Queenslands sugar industry and available to visit your mill to offer expert advice on wear prevention CRUSHER ROLLS Alloys have been selling complete crusher rolls and reshells throughout Australia through our exclusive distributorship of SB Reshellers

WhatsApp)

WhatsApp)