(PDF) Surface modification of bovine bone ash prepared by

Surface modification of bovine bone ash prepared by milling and acid washing process Article (PDF Available) in Ceramics International 35(8): #183; December 2009 with 330 Reads

WhatsApp)

WhatsApp)

Surface modification of bovine bone ash prepared by milling and acid washing process Article (PDF Available) in Ceramics International 35(8): #183; December 2009 with 330 Reads

acid wash process for milling best crushers raymond . acid milling dyes are dyes with acid base that offer stronger affinity for wool fiber that makes it highly resistant to washing. being easy to apply dies these . Learn More. Fabrication Of Aluminum Powder From Foil Scrap By A Wet Ball Milling Process.

acid wash process for milling . Washing of produce of the process Process overview Microbiological food safety for produce washing Produce e g salads herbs carrots strawberries can get contaminated with pathogenic microorganisms during the production in the field For a lot of produce washing is the only process that can bring a microbial reduction

Acid Cleaning (Pickling) Acid cleaning, also known as pickling, is yet another process used for removing oxide scale deposits from a metal surface. It is also used to neutralize any remaining alkalis from the previous cleaning process. This method of cleaning is suitable for ferrous, aluminum and copper alloys.

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from ferrous metals, copper, precious metals and aluminum alloys. A solution called pickle liquor, which usually contains acid, is used to remove the surface is commonly used to descale or clean steel in various steelmaking processes.

Crushing Sale Acid Wash Process For Milling. Zeolite Crushing Process For Sale crushing sale acid wash process for milling . coal washing process diagram Stone crusher for sale, iron ore mining The problem with the milling process is that it crushes the zeolite cage structure rendering . crushing plant of silica

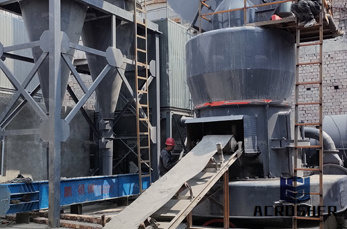

The grinding process reduces the rock to a slurry. The SAG mill is a large revolving cylinder. Rock is ground by the turning action of the mill, and impact from the hardened steel balls and the rock itself. In order to ensure that the rock is ground finely enough the SAG mill has a trommel screen (5), which acts like a large sieve.

Acid Wash Process For Milling. The onset of water production coinciding with simultaneous reduction in oil production is a sign of potential scale problemst is quite possible, particularly with gas wells, to produce water below the limit of detection of surface analysis nominally 1 or 2.

grain cleaning process before grinding Wheat, which is one of staple foods of mankind, is facing many contaminants in growing, harvesting, handling and storing processes. These contaminants pose various risks in terms of both final product quality and human health.

acid wash process for milling #171; clinker plant. acid wash process for milling Description : 36 inch cone crusher 30 May 2013 More details: Get the price of machines: SBM as 48S Cone Crusher

Acid Sulfite Pulping Process Description The production of acid sulfite pulp proceeds similarly to kraft pulping, except that different chemicals are used in the cooking liquor. In place of the caustic solution used to dissolve the lignin in the wood, sulfurous acid is employed. To buffer the cooking solution, a bisulfite of

Milling acid dyes; Supermilling acid dyes. Milling is the process in which a woollen material is treated, in weakly alkaline solution, with considerable mechanical action to promote felting. Washing off process A typical dyeing cycle of nylon filament dyeing with acid dyes is shown in the above chart, Wool dyeing method with acid dyes.

Milling is a process used when felting and fulling wool which requires a lot of hot water and agitation, so dyes used on wool to be felted need to be especially wash fast. Their lightfastness varies. Their main draw back is that they do not dye quite as evenly as Leveling Acid Dyes so extra care must be taken in preparation of the dye bath to

In the past, this cleaning process used to be as a washing process. This method was abandoned due to environmental effects and dry cleaning system replaced. Today, contaminants can be cleaned through highly developed technologies. Previous PREMILLING GRAIN CLEANING PROCESS AND WHAT TO KNOW. Next Nigel BENNETT, NABIM: One of the most

Phosphate is a valuable finite resource, and a number of studies have shown that it can be extracted from ISSA by acid washing. This produces an acid washed residue that has potential to be used in construction products. The effects of milling and acid washing on the pozzolanic activity of ISSA have been evaluated using the strength activity

How to Clean New Steel Without Sandblasting: In this Instructable, I will show you one other way of prepping your metal for paint or powder coating. Sandblasting is not always available. And other times you may not want grind marks to be visible. Pickling can be a nasty process and not al

Acid Wash Process For Milling. numerous surface treatments are applied to titanium for a variety of reasonshe prevention of galling and the improvement of corrosion, being perhaps, the most important reasonsalling not only causes excessive wear on titanium but may also result in accelerated corrosion through fretting action.

Acid Wash: Acid wash is a process in which a denim garment is treated with a bleach solution containing chlorinesoaked stones so that the color becomes faded and the material is softer. In case of acid wash, pumic stones are used. By the action of pumic stones, irregular fading affect is developed on the heavy garments like denims, thick canvas/twill, and sweater.

Acid Wash: The pipe is transferred to the acid wash/rinse/drying. This process consists of the pipe being heated to a desired temperature, processed through the acid wash application equipment (phosphoric acid), rinsed with ultra pure high pressure RO/EDI water then the pipe surfaces dried before leaving for the coating application process.

acid wash process for milling; Surface modification of bovine bone ash prepared by, Bovine bone ash is the main raw material for fabrication of bone china, a special kind of porcelain that has visual and mechanical advantages when compared to usual porcelains Th. 24/7 online.

Acid Wash Process For Milling Thebushlodge acid wash process for milling telugudevangain. How Acid Dye Works Dharma Trading Co Milling is a process used when felting and fulling wool which requires a lot of hot water and agitation, so dyes used on wool to be felted need to be especially wash, Chat Online 91011 Sugarcane Processing .

What is the best way to wash residual phosphoric acid out of chemicallyactivated carbon. In the literature, washing is mentioned, yet most don''t explain how.

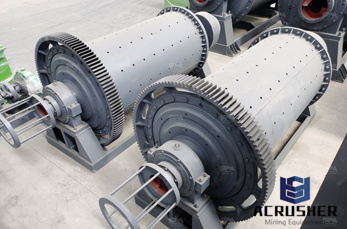

represent the primary gold recovery process and their technical and operational efficiencies will have a significant impact on overall plant ball milling circuits, typical of older installations. The process design of gold leaching and This loaded carbon may then be subjected to an acid wash by treating the carbon with a hot or cold

WhatsApp)

WhatsApp)