Grinding Mill Plant YouTube

04/06/2008#0183;#32; Make your own Animal Feed, Fish Bait, Pellet Mill, Hammer Mills amp; Briquette Machines Duration: 2:14. Bio Green Tech 659,143 views

WhatsApp)

WhatsApp)

04/06/2008#0183;#32; Make your own Animal Feed, Fish Bait, Pellet Mill, Hammer Mills amp; Briquette Machines Duration: 2:14. Bio Green Tech 659,143 views

Ball Grinding Mill Micronized Plant Get Latest Price This is an effective Unit mainly for Calcite amp; Dolomite Minerals Which carries out the process right from crushing of Stones Up to the Sizes of 6 mm to finally Grinding the tune of D9710 Microns sizes with RAVll amp; RAV III Classifier amp; Giving approximate Production of 800Kgs respectively per hour basis.

The Universal Cutting Mill PULVERISETTE 19 is utilized to finely mill cannabis plant material in preparation for SFE processes. The efficient and precise reduction in particle size optimizes oil output and formulation. Introduction . The fastgrowing field of cannabis extraction still holds many process inefficiencies that can be easily overcome. A bottleneck often encountered is the packing

Micro Powder Mill . mesh453m Production capacity : 10300t/h Applicatio : Products can be used for calcium carbonate, talc, calcite, dolomite, potassium feldspar, graphite and other Mohs hardness of 7 below the water content of less than 6% of the mineral ultrafine grinding, product fineness up to D97 5m. Advantages: Low investment costs, low loss of wearing parts;

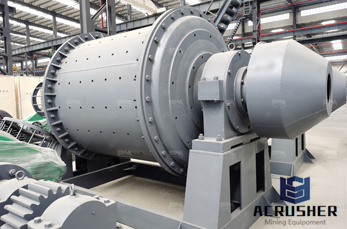

Application of Ball Mill and 30/80 Grinding Plant Our machines are involved in Grinding of Quartz and Feldspar where our Ball Mill does grinding of Fine Mesh(150350 Mesh). Our 30/80 Mesh Grinding Plant grinds grand size of 0 to 9 mm which finds its applocation in Ceramic Unit, Glass Industry, Floor and Wall Tile Plant, Sanitary ware amp; also as a raw material in many other industry, It is also

28/09/2020#0183;#32;UK: Welding Alloys says that it has carried out maintenance on a vertical roller mill at HeidelbergCement subsidiary Hansons /yr Purfleet slag plant in Essex, repairing the mills Loesche 46 2+2S grinding table and rollers. The company said that the mill, which had ground 3500t of granulated blast furnace slag (GBFS), was in urgent need of refurbishment.

Coal grinding mill plant is a crucial additional devices pertaining to coalpowder furnace, there are 3 solutions to break the actual coal group along with mill these directly into natural powder,it is actually crushing, impacting and even grinding. Coal grinding mill plant Structure. Air swept coal grinding mill plant may be the primary products throughout cement plant for both drying out and

Steel Slag Vertical Mill; Clinker Grinding Unit; Coal vertical mill; Raw material vertical mill; Vertical cement mill; Coal mill; Rod mill; Cement ball mill; Slag Vertical Roller Mill; Crushing. Impact crusher ; Hammer crusher; Limestone crusher; Jaw crusher; Calcination. Cement Rotary Kiln; Lime rotary kiln; Vertical Lime Kiln; Ore dressing. Vertical roller mill; Ball mill; Stone Crusher

Home gt; Products gt; Grinding Plant gt; Ball Mill; Ball Mill Grinding. Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrousamp;nonferrous metal mine, coal, traffic, light industry, etc. Applications: Black

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding. Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet

WhatsApp)

WhatsApp)