Hammer mill For The Homestead For Making Feed For Our

#0183;#32;This old vintage hammer mill will be working again soon one day. It''s needing some TLC In which it will receive from my self. After it''s all back in good wor...

WhatsApp)

WhatsApp)

#0183;#32;This old vintage hammer mill will be working again soon one day. It''s needing some TLC In which it will receive from my self. After it''s all back in good wor...

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little machines have numerous industrial applications, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production

Diy Rock Hammer Mill. Au j 83 124130 jan005 development and testing of a hammer mill aasir department of mechanical engineering, federal university of technology minna, niger state, nigeria abstract the hammer mill was designed and constructed from locally.

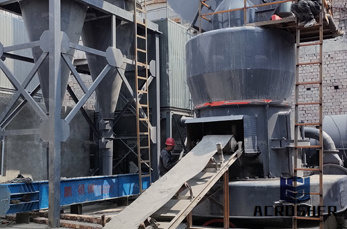

Hammer mills are versatile machines for material size reduction. Applied to ore milling applications, our hammer mills can produce flourfine rock powder. Glass pulverizing, rock recycling, porcelain recycling, and similar material reduction projects achieve slightly variable output sizes,

Rock Hammer Mill Crusher, Wholesale Various High Quality Rock Hammer Mill Crusher Products from Global Rock Hammer Mill Crusher Suppliers and Rock Hammer. Read More. how to make your own impact hammer mills for rock video how to make your own impact hammer mills for rock video These portable impact mill rock crushers that we produce are high qualityWe sell all the items.

PDF | On Dec 18, 2015, Hanafi A Radwan and others published DESIGN AND EVALUATE OF A SMALL HAMMER MILL | Find, read and cite all the research you need on ResearchGate

The 911JAC12K MINI Rock Crusher is our most small rock crusher for the smallest budget. It contains all the high quality precision precut and ready to weld machined parts of a small jaw crusher. It is a Doityourself version of on Mini Crusher.. You need to supply the 1 HP motor of your choice.. This 1 x 2 homemade rock crusher is mini in size but large in crushing performance.

Rock Hammer Mill Design. if a hammer pin must be reused, it should be rotated end for end to make sure the hammers are located in a new spot on the hammer pinxcessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed surges that cause the hammers to rock on the pins or the.

Our hammer mills guarantee uniform grinding, noiseless operation and less heat buildup in all pharmaceutical processes. Whether you need standard or customized hammer mills, SaintyCo offers many series for specialized shredding applications. The cGMP compliance and innovative design make SaintyCo hammer mills the most soughafter in this industry.

hammer mill for rock how to make 3d milling machine; crushing 3d milling south africa newcambridgeschool . Hammer crusher, Hammer broken machine, Rock crusher, ball mill 10 ton per hour cost hammers to process grain uniformly The capability to hammer 34 tons per hour Millmilles with

#0183;#32;A homemade hammer mill is shown in this video. It can be used for crushing stones and all other nonmetallic materials. For hammer mill operation view the vi...

Hammer Mill | fBC M#225;quinas. Hammer Mill Features The Hammer Mills manufactured by fBC Machines, Aggregates and Mining are suitable for low abrasive materials, typically used in dolomite milling industries, reuse of ceramic and refractory materials, granite and basalt, where high mechanical strength and resistance to wear and impact are required.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Begin installing hammers by putting a hammer in the first space, put the hammer on the rod with the rod through the hole nearest the cutting tip, then skip 3 spaces and put in the second hammer. Continue this spacing to the end of this rod.(note) While installing fixed hammers rotate the hammermill clockwise looking back from the engine.

For high production of crushed coal it is better to use the hammer mills having higher contact surface of hammer. Hence, it is easy to produce the high rate of crushing coal with in less purpose of the crushing is to produce the coal having size of less than 3mm (More than 3mm) and the moisture content is 1012 percent .The type of hammer mill used is a Reversible swing hammer with

A Chain Mill is a total amateur''s tool for quot;crushing or grindingquot; rock. It is a set of chains attached directly at the end of a 1700+ RPM motor. The chain will beat your rock to bugdust, pulverise it, and any gold it might contain, into a size fraction so fine you will not be about to recover it using gravity equipment.

#0183;#32;This is a demonstration for a client running a 12quot;x9quot; hammer mill dry with a 1 mm bar gap spacing. At the end of the video we show the results of the test us...

Industrial Hammer Mill Crusher Application Usage. Agricultural Industry: Common applications include crushing animal tankage, animal feed, grains, and agricultural limestone; Energy Industry: Reduce the size of materials such as coal, corn, bagasse, wood, corn stalks, biomass and biofuels, and more; Aggregate Industry: Common materials that hammer mills can finely crush include gypsum, shells

how to make your own impact hammer mills for rock videohomemade rock crusher plans videos YouTube 22 Apr 2014 . Homemade diesel rock crusher. Read More. China Hard Rock Hammer Mills China Hard Rock Hammer Mill, .

Metallurgical ContentHammer Mill Working PrincipleCapacity of Hammer Mill CrushersHammermill Grinder discharge product size distributionBasic Hammer Mill Operational ConceptsJeffrey Swing Hammermill PulverizerHammer Mill Capacity The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far

WhatsApp)

WhatsApp)