(PDF) Cement Manufacturing ResearchGate

PDF | On Dec 9, 2015, Momen Marwan Mohsen published Cement Manufacturing | Find, read and cite all the research you need on ResearchGate. Research Proposal PDF Available. Cement Manufacturing

WhatsApp)

WhatsApp)

PDF | On Dec 9, 2015, Momen Marwan Mohsen published Cement Manufacturing | Find, read and cite all the research you need on ResearchGate. Research Proposal PDF Available. Cement Manufacturing

The UN Global Compact and the proposals around the reduction of CO 2 emissions, the commitments made by different countries and the new trends and requirements of the cement sector, are all encouraging the industry to adapt rapidly to the demands to produce cement through sustainable methods. The cement industry is currently adjusting and adopting new and improved measures to

17/12/2018#0183;#32;The cement is transported to readymix concrete companies In 2016, world cement production generated around billion tonnes of CO2 equivalent to 8% of

Jun 10, 2014#0183;#32; is cement ? of Cement Manufacturing process. of Kiln process. burn wastes ? 2. Portland Cement . A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials. . Portland cement is a powder that is the active

cement product manufacturing; premises, in relation to an operator, means the premises at which the operator carries on concrete batching or cement product manufacturing; weigh hopper means plant or equipment by which the ingredients of concrete are weighed before being loaded into an agitator. 3. Minimization of dust

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water

Cement is the largest manmade material in the world. With the global population set to hit 8 billion soon, the demand for cement is about to skyrocket to unprecedented levels. However, cement manufacturing is linked inexorably to the ongoing phenomenon of climate change. Greenhouse gases like CO2 trap the suns heat and cause the average temperature to increase in the world.

Here is a sample business plan for starting a concrete block manufacturing company. A Detailed Concrete Business Plan; If you have done your homework, you should know by now that a business plan is a musthave resource for this business. A good business plan will let the entrepreneur see all of the details regarding the business. Your business plan must include your startup cost, location

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages. For a more detailed account of the cement production process, see the

Welcome to the Cement Industry Federation. The CIF is the peak industry association for manufacturers of clinker, cement and cement products in Australia. Our membership accounts for 100 per cent of Australian integrated clinker and cement production. More than 5,000 people are directly or indirectly involved in the production of clinker and cement mostly in regional areas. Industry Report

Portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a limestone from the Isle of Portland.

The definitive resource on all aspects of cement manufacturing addresses the current issues facing the industry. This twovolume, limited edition is a must have reference for personnel involved in the cement industry including production, quality assurance, process engineering, energy issues, health and safety, environmental issues, and analytical techniques.

CONCRETE BLOCK MANUFACTURING BUSINESS PLAN TEMPLATE. A concrete block business is crucial to the building industry. If you have a strong desire to float your business, this concrete block industry business plan sample will be beneficial to you. You

Cement Manufacturing Process: What is Cement made of.

Cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction. Cements of this kind are finely ground powders that, when mixed with water, set to a hard and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

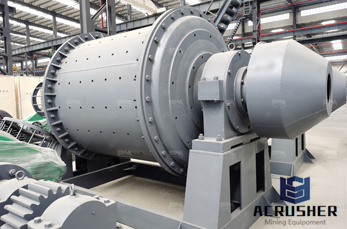

3/10/2017#0183;#32;Manufacturing Of Cement. Manufacturing Of Cement. by any one of the two methods : (i) Dry process, and (ii) Wet process. In both these processes the three distinct operations of (a) Mixing, Ball mill (b) Burning, Rotary kiln and (c) Grinding are carried out. 1. Dry process. In this process lime stone and clay are ground separately to tine powders and are then mixed together in the desired

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

WhatsApp)

WhatsApp)