Ball Mill by Wichita Buggy Whip Homemade ball mill

Oct 17, 2017 Homemade ball mill constructed from an electric motor, pillow bearing, shafting, pulleys, heater hose, steel collars, and lumber.

WhatsApp)

WhatsApp)

Oct 17, 2017 Homemade ball mill constructed from an electric motor, pillow bearing, shafting, pulleys, heater hose, steel collars, and lumber.

Dec 23, 2019 How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

Ball mill Wikipedia, the free encyclopedia. A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of the shell may be either horizontal or at a small angle to the horizontal It is partially filled with balls The grinding media is the balls,. Chat now Building a Ball Mill for Grinding Chemicals . Get price

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

A tower mill is a type of vertical windmill consisting of a brick or stone tower, on which sits a wooden ''cap'' or roof, which can rotate to bring the sails into the wind.. This rotating cap on a firm masonry base gave tower mills great advantages over earlier post mills, as they could stand much higher, bear larger sails, and thus afford greater reach into the wind.

4. Colloid mill is used for grinding, dispersing and homogenizing of ointment, cream, gels, and high viscous fluids in one operation. Advantages of Colloid Mills. 1. It has a wide range of use including comminution of slurry fluid materials. 2. No pressure is required for ionization. 3. The machine is simply constructed. 4. It can be easily

Ball Mills NIDECSHIMPO CERAMICS. PTA01 Ball Mill has a compact design that is constructed using powdercoated steel for long lasting durability The PTA01 model accommodates one jar from 1liter to 10liters PTA02 PTA02 Ball Mill has a compact design a slightly larger footprint from the PTA01 that is constructed using powdercoated steel for long lasting durability

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

The ball mill is one of the most important pieces of equipment in making fine for a ball mill, but one that is constructed yourself can be made to mill powder... Read more. A Ball Mill Lloyd''s plan gives all the patterns to build a nice milling cabinet with its own stand.

Download Citation | Study of BBD Ball Mill Load Measure Method Based on Rough Set and NN Information Fusion | Through analyzing the factors influencing BBD ball mill load and the measure

#0183;#32;To make a ball mill, start by building a wooden platform and attaching a motor underneath it. Then, cut a slit into the wooden platform for the belt to pass through and attach casters to the platform for the container to sit on.

how is a ball mill constructed How Is A Ball Mill Constructed . how to make a ball mill ball mills are a special instrument used to break up hard solids into a fine powder if everything has been constructed properly the belt should be taut against the cylinder if the belt is not taut you may need to lower the height of the.

Gold Point Mill, located is on United States Forest Service Road 222 near Elk City in Ido County, was listed on the National Register of Historic Places in 2000.. The building, on a hillside, is a shedroofed rectangular building constructed in 1936 which housed machinery for amalgamation and concentration of gold ore.

Ball milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase. 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig. ), under wet or dry instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant. 22 Graphite (50 g) was ground in

Renewable energy is the future of energy generation. World is turning towards solar energy and wind energy to cope up with the current carbon emission and de...

Through the centuries, cotton fiber was traditionally processed by hand, until the early 18th century when the first automated processing machine was invente...

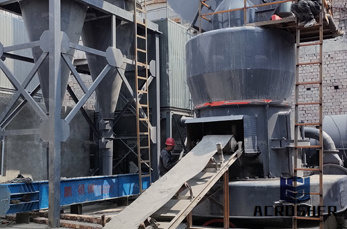

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type.

#0183;#32;Orioles can look to Rays for how winners are constructed. By Rich Dubroff. October 20, 2020 at 8:50 And talk of cheap payrolls means nothing to me. If Elias cuts the payroll down to 30 mil, are we going is that good pitchers typically dont want to sign to play in OPACY where a lazy fly ball to left reaches the seats way

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

WhatsApp)

WhatsApp)