Roll Mill Wall Putty Powder Making Machinery | Crusher

wall putty powder making plants manufacturers. wall putty powder making plant manufacturers. Wall Putty is a white cement based fine powder which provides an ideal base for concrete /

WhatsApp)

WhatsApp)

wall putty powder making plants manufacturers. wall putty powder making plant manufacturers. Wall Putty is a white cement based fine powder which provides an ideal base for concrete /

Wall putty is kind of powder that become paste with water and its used to fix slight surface irregularities and imperfections such as holes, dents and cracks for walls before painting and its plastering material used to fill holes and patches before painting. Buyformula website will teach you the best method for making wall putty with economic raw materials. Formulas are available in PDF

Wednesday 29 August 2007 1:00:00 am. Dear Madam, dear Sir, please give me basic information on making wall putty such as raw materials, process involved, project costs, manufacturing costs, etc.

The invention relates to a putty powder formula for an exterior wall. The formula comprises the following components in parts by weight: 550700 parts of talcum powder, 160200 parts of ash calcium powder, 80100 parts of high strength gypsum powder, 610 parts of cellulose, 610 parts of cassava starch, 35 parts of alum and 240300 parts of water.

Mar 15, 2013#0183;#32;Wall Putty is white cement based, ready to use, ball mill for wall putty manufacturing process in small plant ; grinding powder machine types introduction; How to Putty Drywall | You must cover these butting joints with drywall putty and drywall tape.

About Us. Global Associates is making available a wide range of putty and wall textures since 2007. As a responsible manufacturer and supplier, we perform our duties with utmost sincerity and ensure best possible deals to of Acrylic Wall Putty, Primer Paint, Wall Putty Powder, Living Room Wall Texture, etc, begins in our specialized lab wherein all the processes are handled

Cone Crusher Process Of Making Powder Base Wall Putty. process of making powder base wall putty dubai. Putty Powder. View Video. Wall Putty. Hi friend!The process of manufacturing wall putty involves heating the Production of Cocaine Hydrochloride and Cocaine Base.

wall putty making machine, wall putty making machine offers 589 wall putty making machine products. About 74% of these are Dry Mortar Machines, 9% are Mixing Equipment, and 3% are Mortar Spray Machines. A wide variety of wall putty making

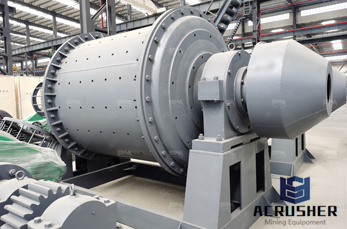

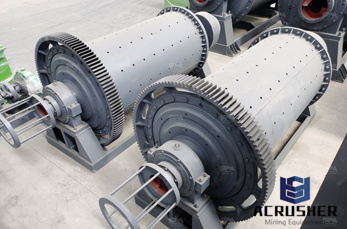

Grinding mill for of making powder base wall putty, wall putty making machine mining equipments applied Machines For Making Wall Putty The is the white cement based wall putty distributor and supplier of wall putty machine, polishing machine, roller

Wall Putty is used to smoothen the surface, to fill the fine pores on the wall surface, to provide firm base for subsequent paint. Wall putty give an elegant look / Aesthetic appeal, more coverage for subsequent costly paints and they protect the wall. There are variegated types of putties for wood too.

Apr 16, 2020#0183;#32;Wall putty can fill in small cracks and holes, and adding a couple thin layers over the wall will improve its appearance and help paint adhere better. Just make sure you prepare the wall and mix the putty properly, apply it in thin coats, and let it dry thoroughly before proceeding.

JK Wall Putty JK White Cement launched a value added product, JK Wall Putty in 2002, as a result of consistent Ramp;D efforts and technology updations. White Cement based JK Wall Putty is the ideal base for beautiful walls, giving the smoothest surface for luxurious and silky interiors.

#183; Wall Putty Powder Making Machinery Heavy Industry. Wall Putty Powder Making Machinery. Wall Putty is a white cement based fine powder which provides an ideal base for concrete / cement plastered walls and ceilings.

Apply one coat of primer before you start applying putty on wall and dry it overnight, minimum 12 and preferably 24 hours. Some putty manufacturers recommend the application of primer before putty and some do not. Therefore, follow the manufacturers instructions

Wall putty manufacturing plant is also called wall putty making machine. It is mainly used to produce plaster plaster mortar includes different kinds, such as, putty mortar for interior and exterior wall, insulation plaster mortar, colored decorative mortar and so on. Because of its wide application, wall putty making machine plays an important role on the construction industry.

Feasibility Report on Wall Puttyprovides an insight into the Wall Putty market in India with focus on uses and applications, Manufacturing Process, Process Flow Sheets, Plant Layout of Wall Putty project. The report assesses the market sizing and growth of the Indian Wall Putty Industry. While expanding a

wall putty powder making plants manufacturers. wall putty powder making plant manufacturers. Wall Putty is a white cement based fine powder which provides an ideal base for wall putty manufacturing process

The basic work flow of a typical wall putty manufacturing machine is as the follows: raw material storage metering ingredients material mixing and agitation finished product packaging, as well as raw material delivery, lifting and dust removal equipment in the putty powder production process. Main Components Of The Wall Putty Making Machine:

Pe250#215;400 Process Of Making Powder Base Wall Putty WBDG The Whole Building Design Guide Web portal for buildingrelated information with a quot;whole buildingquot; focus provided by the National Institute of Building Sciences.

Jul 29, 2018#0183;#32;Wall putty is usually applied with two flatbladed trowelsessentially, larger putty kniveswith one in each hand. The smaller trowel should have a blade thats around 68 in (1520 cm) wide, the larger one about 1214 in (3036 cm) wide. Use the small trowel to

WhatsApp)

WhatsApp)