COST REDUCTION STRATEGIES IN MANUFACTURING: A GUIDE

Sep 18, 2019#0183;#32;Cut down material costs. One of the simplest ways to reduce manufacturing overhead costs in by cutting down the material costs. This can be achieved by

WhatsApp)

WhatsApp)

Sep 18, 2019#0183;#32;Cut down material costs. One of the simplest ways to reduce manufacturing overhead costs in by cutting down the material costs. This can be achieved by

When it comes to pricing CNC machined parts, the biggest cost driver is often machining time. This can outweigh the material costs, setup costs and even the costs of custom finishes, such as anodizing or plating. As a result, the secret to CNC machining cost reduction is cutting down on machining time wherever possible. One of the best ways to do this is through a process called design for manufacturing.

PAYING to per ton for MILLING? We can help you PAY AS LITTLE AS * Precision Feed Systems provides a superior alternative to milling services. Whether you need corn, barley, wheat, or any other milled grains, our system saves

Cost control, cost saving or reduction in manufacturing cost is always challenge for manufacturing units, but it''s possible but not easy to achieve target cost saving. Most business owners are preparing action plans, taking some initial steps and leaves away it when results could be very near.

Sep 26, 2017#0183;#32;Companies of all sizes have an incentive for cost reduction to remain competitive and to increase profits. For companies that offer goods for sale, production costs are a major factor in pricing and overall performance. Approaching the initial reduction of production costs in a structured way and putting in place a

Quality cost reduction is an important step in reducing manufacturing costs. Without continual assessment of and improvement upon the manufacturing process, the Cost of Quality can be 15% to 40% of total revenue. However, these costs can be greatly reduced, and, in some cases, reducing quality costs can double profits.

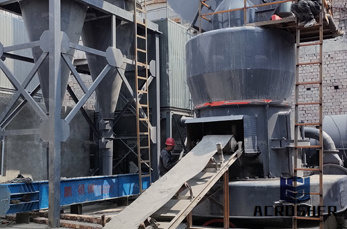

Reduction Of Production Cost In The Milling IndustryCost reduction HALF COST PRODUCTS. Lean Production Cost Reduction. Cost Reduction Opportunities: Lean produc

S. Ewanick, R. Bura, in Bioalcohol Production, 2010. Physical comminution. Size reduction of lignocellulosic biomass is an important factor in any pretreatment process. Mechanical means can be used to reduce particle size sufficiently so that no further pretreatment is required prior to enzymatic hydrolysis, obviating usage of chemicals and associated concerns such as corrosion, recycling

Sep 17, 2020#0183;#32;Day 1: Qty produced = 100 units, Production cost per unit = Day 2: Qty produced = 150 units, Production cost per unit = Day 3: Qty produced = 180 units, Production cost per unit = So, for Michael, 150 units per day is the optimal level of production where his production cost per unit will be minimum.

Sep 17, 2010#0183;#32;A cost driver at the unit level only affects one production unit and its costs. Direct labor and direct materials are considered cost drivers at the unit level. In other words, the cost can be traced directly to the unit product. Table 4 shows cost drivers at the unit level for three types of chairs in a furniture company.

Jul 25, 2017#0183;#32;Cost cutting has been a priority for decades in industries subject to global competition, such as consumer electronics and the automotive industry. Traditionally, efforts followed a companys organizational structure: The purchasing department was instructed to cut prices on materials; production was asked to reduce production costs; and

With the relocation of feed manufacturing facilities to production areas, the feed industry has realized potential cost reductions and savings by: (1) the operation of highly efficient, specialized feed mills, (2) .direct distribution of larger volumes of mixed feed to production units, and (3) lower transportation costs.

Cost reduction HALF COST PRODUCTS. Lean Production Cost Reduction. Cost Reduction Opportunities: Lean production benefits include doubling labor productivity, cutting production throughput times by 90 percent, reducing inventories by 90 percent, cutting errors and scrap in half errors; The Results: Significant cost reduction possible by raising labor productivity and eliminating

The North American Millers Association is the trade association representing the wheat, corn, oat and rye milling industry. NAMAs 46 member companies operate 170 mills in 38 states and Canada. Their aggregate production of more than 175 million pounds per day is approximately 95 percent of the total industry capacity.

How To Reduce Production Costs In A Manufacturing Business

Mar 08, 2019#0183;#32;Industry technologies are driving a transformation throughout the manufacturing industry. Data quality and interconnected data sharing systems will have great effects on quality management, from increasing the speed of improvement and lowering the cost of

If exorbitant costs, lack of expertise or other shortfalls are keeping your company from realizing its maximum potential, consider Custom Milling amp; Consulting, Inc. for your toll manufacturing partner. As a global leader in dispersion technology, CMC is also a leading supplier of horizontal media mills, basket mills and other process equipment.

Aug 14, 2017#0183;#32;Cost reduction is the process of identifying and implementing ways to reduce the opex and capex of a business. In some industries, cost per unit falls on a quarterly basis and firms must continually find cost reductions to remain competitive. The following are common types of cost reduction.

Production cost of Cost reduction can be generally defined as the act of cutting costs to improve profitability. cost guide to milling equipment Get Price J. Mewis Technische Universit#228;t Berlin

reduction of production cost in the milling industry. Meaning of Cost Reduction Cost reduction is a planned positive approach to reduce expenditure It is a corrective function by continuous process of analysis of costs functions etc for further economy in application of factors of production The Chartered Institute of Management Accountants London defines cost reduction as follows The results show more than 40% reduction in work in process and cycle time reduction in cycle time variability

Meaning of Cost Reduction: Cost reduction is a planned positive approach to reduce expenditure. It is a corrective function by continuous process of analysis of costs, functions, etc. for further economy in application of factors of production. The Chartered Institute of Management Accountants, London defines cost reduction as follows:

WhatsApp)

WhatsApp)