Dynamic classifiers improve pulverizer performance and more

#0183;#32; Sims Power Plant in Grand Haven, Mich. Dynamic classifiers were retrofitted to three BW Model EL56 ball mill pulverizers feeding an 83MW BW frontwallfired boiler.

WhatsApp)

WhatsApp)

#0183;#32; Sims Power Plant in Grand Haven, Mich. Dynamic classifiers were retrofitted to three BW Model EL56 ball mill pulverizers feeding an 83MW BW frontwallfired boiler.

FCB TSV Classifier in Kosjeric (Serbia) Tromp curve FCB TSV Classifier in Chelm (Poland) CEM IIAM 3800 Blaine CEM I 4750 Blaine Cut size 37 #181;m Cut size 18 #181;m FLEXIBILITY FCB TSV Classifier can be combined with different types of mills: ball mill, FCB Horomill#174;, and vertical mill (Emill, Raymond mill, roller mill).

Ball Mill Circuit Classification System Efficiency, 22 Apr 2018 Ball Mill Circuit Classification System Efficiency It also depends on the ability of the classification equipment to remove the fines that areBall mill, A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing Highquality ball mills are potentially expensive and can grind mixture particles to

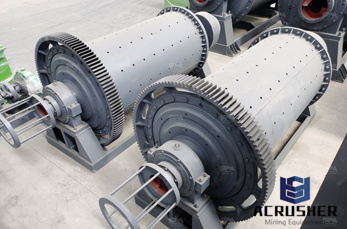

Ball Mill with Classifying System. Ball mill is also known as rotary ball mill. Inside the ball mill, there are many different sizes of balls, which is called ball media. And when the ball mill rotates, the ball media and feed limestone inside the ball mill will collide and crush so as to make fine and ultra fine calcium carbonate powder.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The FCB Emill is a very reliable grinding mill based on a robust and proven design. It offers low maintenance and a constant product quality. Furthermore, the material bed grinding concept allows for a reduction of 50% of the power consumption compared to the ball mill.

Ball Mill with Classifying System. Ball mill is also known as rotary ball mill. Inside the ball mill, there are many different sizes of balls, which is called ball media. And when the ball mill rotates, the ball media and feed limestone inside the ball mill will collide and crush so as to make fine and ultra fine calcium carbonate powder.

hosokawaalpinede: Micro ACM Classifier Mill. The Mikro ACM classifier mill was the first classifier mill on the market in 1962 Since then, the ACM has been continuously developed and adapted to the changing needs of the market, ACM CX The coaxial bearing arrangement of both classifier and grinding disc shafts makes a vertical product discharge possible, which in turn prevents .

Zhengyuan is China powder grinding mill manufacturer, offer jet mill, impact mill, ball mill, roller mill, plastic pulverizers. We also provide accessories for powder grinding equipment, like air classifier, dust collector and rotary feeder. We offer fine grinders for different uses, such as for grinding large quantities of material, superfine grinder mills for grinding sample material and

Ball Mill. LV Classifier and its unique seperation concept The principle of classification is same for all the classifier but what makes LV classifier unique is its three phase classification compared to single phase classification in modern classifier.

#0183;#32; Sims Power Plant in Grand Haven, Mich. Dynamic classifiers were retrofitted to three BW Model EL56 ball mill pulverizers feeding an 83MW BW frontwallfired boiler.

High Efficiency Ball Classifier Mil. why do ball mills have such high circulating loadsthe ball mill grinds the cyclones separateut the pump neither grinds nor separateso what is the purpose of having such a big pump to maintain high circulating loads in our grinding circuita recent grinding bulletin addresses this question f.

Ball Mill and Classifier System for Calcium Carbonate Plant. In calcium carbonate production line with high capacity, ball mill usually works with air classifier to obtain fine and ultra fine ground calcium carbonate powder. Firstly, the required sizes of raw materials will be feed into the ball mill for grinding.

Air Classifier for Calcium Carbonate Top Daswell Ball

* Mills come along with a control panel and has an automatic lubrication unit. * Ball/Rod Mills can be specially designed for wet or dry grinding. Compared to similar equipment, Ersel Ball/Rod Mills provided low energy consumption and high efficiency, as a result of our improvements based on our Ramp;D studies and process experience.

Classifying And Ball Mill Production Line Ball Mill . Ball mill ball mill is selected on the basis of hardness grindability index of material feed size product size capacity right selection of grinding ball and rod can improve grinding efficiency and reduce energy consumption classifier different series of classifier could be selected depending on different fineness of

Ball Mill, Ball Mill Classifying Production Line, CaCO3 Grinding Mill manufacturer / supplier in China, offering 2~10um Heavy Calcium Carbonate Production Line, Barite Powder Grinding Air Jet Mill for 245microns Ultrafine Grinding, Ultrafine 5000 Mesh Air Classifier Automatic Mill Air Classifier Mill

The ACM classifier mill was the first classifier mill on the market in 1962. Since then, the ACM has been continuously developed and adapted to the changing needs of the market. With over 1000 references worldwide, it is used in every industry: Chemicals: bisphenol, tartaric acid, EPVC, fungicides, herbicides, stearates.

WhatsApp)

WhatsApp)