Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types

WhatsApp)

WhatsApp)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types

Cement Grinding Cement Plant Optimization. Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine ( Blain) cement Grinding operation is monitored for following parameters to ensure objectivity and economy of operation Grinding Operation Objectives and KPIs

CHAENG cement vertical roller mill is featured with relatively simple process, easy operation, less investment in process equipment, energy saving, and environmental protection. Cement grinding station is composed of dust collector, bucket elevator, belt conveyor, spiral conveyor,/ high efficiency ore dressing machine and so on. The Performance Characteristics of Cement Grinding Station:

1) Large throughput rates: Vertical mill is a closedcircuit system grinding. When raw materials are ground in the mill, they are directly sieved into the classifier, and the qualified fineness is will be collected, while the unqualified coarse powder falls back to the mill for process. The machine continues to

operation description of a grinding machine in cement mill. ball mills are predominantly used machines for grinding in the cement industry. process measurements Read more clinker grinding operation cost Newest Crusher, Grinding

Drive motor moves around flexible coupling to rotate vibrator,and then producing enough vibrating force,then the body of the mill does periodic motion,and to continuously transfer the force to all the materials (raw materials and medium) in the roller,the material is crushed by extruding force between medium and the grinding materials .during the process We can lower down the temperature inside the mill chamber

Grinding Machine Operations: Surface grinding operation: It is used to make a flat surface, the rotating grinding wheel removes the material from the top surface of the workpiece gives a flat look. Cylindrical grinding operation: This type of grinding operation is performed only for cylindrical jobs.

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the regrinding; powder

Grinding Machine Operations: Surface grinding operation: It is used to make a flat surface, the rotating grinding wheel removes the material from the top surface of the workpiece gives a flat look. Cylindrical grinding operation: This type of grinding operation

TC 9524 Chapter 5. GRINDING MACHINES. Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel. When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpiece.

With the unprecedented development of cement industry, the development of grinding machine industry is very quick. The legislative process system of grinding mill process simple, low unit power consumption, cement stable product quality and convenient operation has been all users.

Concrete grinders and concrete scarifiers also known as planers, milling machines and rotary cutters will grind away concrete and leave it smooth and prepped for coating.

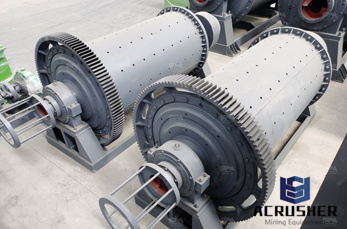

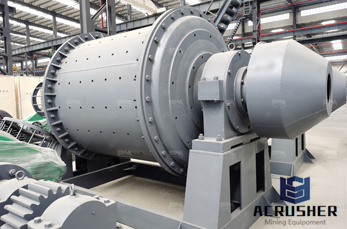

6. Iron slag grinding line 7. Cement clinker grinding line 8. Graphite powder grinding line Features of Ball Mill: 1). the ball mill is an efficient grinding tool which grind various types of material into fine powder. 2). two grinding techniques can be used: drytype grinding and wettype grinding.

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind concerned with reducing the energy consumption of the grinding process

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc,and the ball mill can grind various ores and other materials with dry type and wet type.

Grinding technology and mill operations course for the cement industry. This course provides an indepth understanding of grinding theory and equipment and gives operators the tools to audit your equipment and systems. Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical

Cement Mill is mainly used for grinding various cement clinker or other materials in building material, metallurgical, electric and chemical industries. 2. Sorts amp; Features: a. Common Cement Mill It is mainly used in cycle grinding system, with features of high grinding efficiency, high production, low

Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory, Find Complete Details about Small Scale Cement Clinker Grinding Plant And Packaging Unit In Cement Factory,Clinker Grinding Plant,Cement Grinding Machine,Cement Clinker Grinding Machine from Supplier or ManufacturerXinxiang Great Wall Machinery Co., Ltd.

WhatsApp)

WhatsApp)