Ball Mills an overview | ScienceDirect Topics

Ball Mills. Ball mills have been used for the preparation of coaloil and conventional coalwater slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al., 1984).

WhatsApp)

WhatsApp)

Ball Mills. Ball mills have been used for the preparation of coaloil and conventional coalwater slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al., 1984).

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

End Mill Sizes Many people have asked that we create a chart showing all of the end mill diameters. So we have done that, and want to make all of our customers aware. You can find this in the tab called quot;Technical Infoquot; and the link quot;End Mill Sizesquot;. As you view the chart you will notice some sizes are linked also. This will take you to a page where all of that diameter''s end mills are listed.

ball mill capacity alog. ball mill production capacity ppt postcatcherin. The types of ball mills: batch ball mill and This charts show the cost in US Dollar of ball mill, by knowing the capacity Calculate Ball Mill Grinding Capacity The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical Calculate Ball Mill Grinding

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

End Mill Size Chart (pdf) The above link provides a printable and downloadable chart of the table below. This table shows end mill diameter sizes for inch, metric, and micro milling bits from quot; to 1quot;. All of these sizes can be searched by clicking the End Mills tab at the top of the page.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and

Capacity And Size Of A Ball Mill. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Small / large size lab scale ball mill machine / grinding ball mills. Contact Directly amp; Get Quotes!! Wholesaler, Suppliers and Exporters, Manufacturer Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM 44110) Laboratory Ball Mill 20 Kg capacity

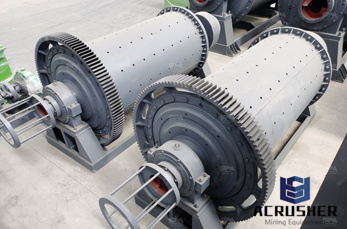

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Ball Mill Screening Capacity . Continuous ball mill capacity 500 hr crusher and mill continuous ball mill capacity 500 hr crusher and mill ball mill bm 500 chocolate spfproduction Chat Online 500 Kg Ball Mill Batliboi make 300 kg to 500 kg ball millcrusher manufacturersower plant engineering free ebook download as pdf file f text file t or read book online for.

Principle Desgin Of Ball Mill . ball mill structure principle chart Oksidasi Oksida Ball Mill Principle Price Ball Mill Principle Price Production capacity 065615th Feeding Size 25mm Discharging Size mm Ball mill is also known as ball grinding mill Ball mill is the key equipment for recrushing after the crushing of the materials It is widely used in Chat.

Effect of ball size 29 Empirical approaches 29 Probabilistic approaches 33 Abnormal breakage 36 Effect of ball mixture 37 Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3

Equations of the design By knowing the capacity quot;Cquot; {ton} of the feed; we can get approximately the length quot;Lquot; {mm} and diameter quot;Dquot; {mm} of the batch ball mill, form **D = *(C) + **L= *(C) + 1854 Volume of mill = ^2 The bulk volume of balls charge ratio to the volume of mill is known as {Filling ratio} and its range is {3045%} ^2 _____ ** Note: There

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear amp; Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales _____ Since 1911 phone fax B Ball Mill Capacity amp; Dimensions

WhatsApp)

WhatsApp)