Comparison of Wet and Dry Grinding in Electromagnetic

Dry grinding and classification circuit: (a) Idea of the circuit: 1feed stream, 2mill working chamber, 3working area with ferromagnetic rods, 4main transport air stream, 5mills output stream

WhatsApp)

WhatsApp)

Dry grinding and classification circuit: (a) Idea of the circuit: 1feed stream, 2mill working chamber, 3working area with ferromagnetic rods, 4main transport air stream, 5mills output stream

Wet Pan Mill for Grinding Gold Ore Brief Introduction: Wet Pan Mill for Grinding Gold Ore is widely used for selecting ferrous metals, nonferrous metals and nonmetals, as well as precious metals like gold and silver. It mainly consists of driving device, frame, water basin, grinding wheels and grinding base, etc. Wet Pan Mill for Grinding Gold Ore grinds ores by wheel driving force: firstly

Identification of Optimal Mill Operating Parameters during Grinding of Quartz with the Use of for wet grinding in overflow ball mills to scaleup results from laboratory tests to larger mills S JDi (1 ), m (4) Beeck R. (1970) proposed that for dry grinding of

operating parameters. Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study. It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated into a complete liberation model. #183; Literature Review

Wet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials. its the best replacement for mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so on.

The effect of ball and mill diameters on grinding rate parameters in dry grinding operation, Powder Technol., 42 (1985) 199208. Gupta and Sharma S., Analysis of ball mill grinding operation using mill power specific kinetic parameters, Adv. Powder Technol., 25 (2014) 625634.

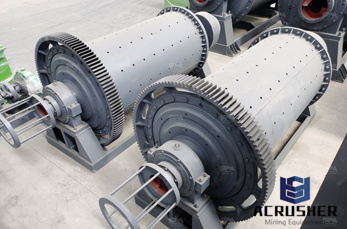

design mining wet ball mill. The basic parameters used in ball mill design power calculations, rod mill or any tumbling mill sizing are material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating solids or pulp density, feed size as f and maximum chunk size, product size as p and maximum and finally the type of circuit

Operating Parameters Of Wet Ball Mill. Parameters of wet ball mills. Ball MillingUniversity of Massachusetts Boston. A ball mill is a type of grinder used to grind materials Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . brittle fibrous (dry or wet) Material feed size 10 mm Final fineness 1 m No. of grinding stations 4 2 .

Material Grinding By Means Of Ball Mills. Material Grinding By Means Of Ball Mills 2 peculiarities of ball mill automation the process of solid material grinding in ball mills has been automated poorly because there were no methods to measure the main parameters of the grinding process such as amount of the material in the mill grinding Pdf Analysis Of Ball Mill Grinding Operation Using Mill

Product Details Parameters. Wet pan mill/grinding gold machine is named by the diameter of roller. 1300, 1350, 1400, 1500, 1600 is suitable for the selection of iron ore, molybdenum ore, lead ore, zinc ore, antimony ore and so on; 850, 900, 1000, 1100, 1200 is

The effect of ball and mill diameters on grinding rate parameters in dry grinding operation, Powder Technol., 42 (1985) 199208. Gupta and Sharma S., Analysis of ball mill grinding operation using mill power specific kinetic parameters, Adv. Powder Technol., 25 (2014) 625634.

#0183;#32;Wet Pan mill. TPH. Feeding Size lt;30mm. Discharge Size Procesible Material gold, iron, molybdenum, lead, zinc, antimony, and so on. AdvantagesPan Mill is now the best and economic replacement for small or medium scale milling machine, such as ball mill, it is currently widely used in the small, medium mineral

Wet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected. With less investment, fast results, small footprint saving power, sturdiness and durability, ease of maintenance and high return on investment. It is the preferred production for alternative ball mill, is ideal for small and medium

wet ball ML in grinding process is mainly measured by the signals to monitor the wet mill operating parameters which present the ball load, material load and water load [11].

Wet pan mill/grind gold machine is also easily installed and maintained, which is the ideal equipment for mine SMEs beneficiation. The operation and maintenance of wet pan mill /grinding gold machine. raw material should be put into the machine after the machine running normally.

Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill 226 #199;.#220;. M#252;h. Mim. Fak. Dergisi, 33(3), Eyl#252;l 2018 1. INTRODUCTION The purpose of this experimental investigate the Grinding, particularly ultrafine grinding, is a unit operation with high energy requirements in the

WhatsApp)

WhatsApp)