Copper Mining Process Direct Smelt

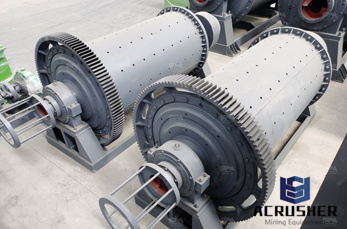

Copper Mining Process Direct Smelt Stone Crushing Equipment The building aggregates equipment of Aamp;C includes not only a series of single equipment of coarse crushing, intermediate and

WhatsApp)

WhatsApp)

Copper Mining Process Direct Smelt Stone Crushing Equipment The building aggregates equipment of Aamp;C includes not only a series of single equipment of coarse crushing, intermediate and

The processes that produce molten metal, similar to blast furnace liquid metal, directly from ore are referred to as direct smelting processes. In some of the processes the objective is to produce liquid steel directly from ore and these processes are classified asdirect steelmaking processes. A. Markoti} et al.

Copper smelting plants separate elemental copper from copper concentrates through multiple sulphide oxidizing stages. The considered smelting process includes a continuously functioning flash smelting furnace (FSF) and several PierceSmith converters operated in batches. Automating scheduling provides advisory information to operators.

The copper is purified to % by electrolysis. The production route described above shows the progression from a rock containing about % copper to a copper cathode of % purity. Leaching. Leaching offers an alternative to copper mining. First, the ore is treated with dilute sulphuric acid.

Copper Smelting an overview | ScienceDirect Topics

A high grade ore produces a high yield of metal. A low grade order produces a low yield of metal. Copper can be extracted from sulfide ores (usually higher grade ores) by direct smelting. The earliest evidence of copper smelting occurs in Serbian artefacts dating from around 5000 BC.

Direct smelting of copper in a single vessel has long been the extractive metallurgists dream. Such a process offers the important alvantage. of (i) maximum use of the energy available from oxidizing the sulphur and iron of the concentrate: (ii) restriction of SO2 emissions to a single constantstrength source; (iii) minimum materials handling and (iv)...

Copper smelting was a technical, complex process which needed a large amount of copper ore so initially it made sense to smelt it near where it was mined. The process also used large amounts of...

Copper smelting plants separate elemental copper from copper concentrates through multiple sulphide oxidizing stages. The considered smelting process includes a continuously functioning flash smelting furnace (FSF) and several PierceSmith converters operated in batches

Smelting is a process of applying heat to ore in order to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind. The reducing agent is commonly a

Figure Smelting Technology Charcoal ore flux m The Egyptian copper smelting furnace was filled with a mixture of copper ore, charcoal and iron ore to act as a flux. It was blown for several hours by foot or hand bellows. By the end of the smelt the copper

copper mining process direct smelt COPPER Copper production Repository Figure 1: Overview of copper production Benefication process Figure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting Smelting

Copper Smelting Process Furnaces Used, ByProducts, There are several methods of copper smelting, the popular ones being reverberatory smelting and oxygen flash smelting. Both methods require the resultant molten copper to be further processed to achieve a grade of % pure copper.

Using todays compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, its roasted, which helps to convert sulfides to oxides. The oxides are smelted to produce matte, which then undergoes several refining processes.

Copper Smelting Process Furnaces Used, ByProducts, and Process Used to Smelt Copper Introduction to Copper Smelting Techniques. Copper ore typically contains only about % of the actual copper mineral,... Mining for Copper Bearing Ore. There are two categories of copper ore; sulphide ore which

Promoting viable handson solutions is the goal of our Stop Mercury Project, and direct smelting is a mercuryfree method of gold recovery from highgrade concentrates. Its a simple and costeffective method that can be done in the field with very little education, equipment or expertise.

Direct smelting of copper in a single vessel has long been the extractive metallurgists dream. Such a process offers the important alvantage. of (i) maximum use of the energy available from oxidizing

WhatsApp)

WhatsApp)