(PDF) DESIGN AND OPERATION OF VERTIMILL#174; FOR

The Vertimill#174; design The use of vertical stirred mills which estimates load volume and installation of the Split system for online particle size estimation in both SAG mill feed

WhatsApp)

WhatsApp)

The Vertimill#174; design The use of vertical stirred mills which estimates load volume and installation of the Split system for online particle size estimation in both SAG mill feed

layout amp b design of feed mills vertical. Different forms and designs of feed mill SlideShare. Daycounter, Inc. Engineering Services. Custom Firmware, Electronics Design, and PCB Layout. horizontal feed mixer design Alibaba. Jun 07, 2016#183; DESIGN PARAMETER 5.

layout 26amp 3 design of feed mills vertical; Feed Mill Design SA Trade Hub. Feed Mill Design By Fred J. Fairchild, P. E. Department of Grain Science and Industry Bulk Feed Loadout Bins Number of bulk product bins based on amount of feed made, number of layout of the mill is started.

GrinderMixers KState Research and Extension Bookstore. dients. Hence, the farm layout with regard to grain bins, soybean meal devices shall be accurate and of suitable size, design, construction case, suppose a feed mill sold product that averaged 50 pounds. the vertical mixer (see Figure 3).

Vertical Roller Mill Price And Performance Advantages Analysis. Feed size: :lt; 10mm. Production Capacity: 518t/h. LUM vertical roller mill can be widely used in cement, power, metallurgy, chemical, production line design output per hour, the size of the production environment and investment cost etc. 70% ball mill system, building space is about milling system 60% and open layout,...

#0183;#32;DESIGN PARAMETER 5. Labor rooms s c a l e Vehicle space Worksho p 3 Offices (12#215;12ft) Laboratory Road Boiler Monitoring room (5#215;3ft) Boile r Warehous e Siloe s Gate 1 5*15 ft Gate2 Essentials of feed mill Facilities arrangementReceiving unit 6. ESSENTIALS OF FEED MILL 1. Fenced land 2. Building for warehouse 3.

Design spectra for sloshing, spectra for long period range in other words, damping ratios for the sloshing phenomena and pressures by the sloshing on the tank roof have been presented. For aboveground vertical cylindrical storage tanks without any restraining element, such as

1958, these mills produced 40 million tons of feed and about 55% was pelleted. In 1968, about 70% of all commercial poultry feed produced in the United States was pelleted. In the Midwest, almost 80% of all manufactured feed is pelleted, crumblized or cubed. The process of producing feed pellets can roughly be described as a plastic molding

vertical spindle position to a horizontal spindle position or can be fixed at any desired angular position between vertical and horizontal. The saddle and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operators choice. SAFETY RULES FOR MILLING MACHINES

The internal mounting design of the door allows the control pendant to be mounted to the front of the machine, in an operatorfriendly position. Operator Convenience Features The UMC750s operator convenience features are mounted to the front of the machine for easy access, including a toolholder storage rack, work table, toolholder vise, storage tray, and washdown hose.

Vertical mixers are the most common type found in small livestock feed mills. However, the vertical type is less well suited to aquaculture, poultry and fish feeds than the horizontal type, which are much more efficient in blending in small quantities of liquids (such as added lipids) or in mixing ingredients with different particle sizes.

Layout Amp Design Of Feed Mills Vertical Main Contents. dry grinding attritors amp small media mills custom in feed . amp Suppliers on GlobalSpec. #187; Learn More. vertical layouts of feed factory. layout design of feed mills vertical, Mining and .

#0183;#32;Different forms and designs of feed mill 1. Different forms and Designs of feed mill 2. Feed is produced for a number of animal types such as livestock (including poultry, swine, and ruminants), domestic animals (such as pets), and fish (for aquaculture).

1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 211 Directdrive portable mixer. (Courtesy of Lightnin.) mixers are mounted on the vertical centerline of a tank with bafes, but may be offcenter or offcenter, angle mounted.

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick.

vertical and horizontal layouts of feed mill. ComputerAided Manufacturing Course Descriptions. Includes operation of vertical and horizontal manual milling machines, Layout and design: Patricia Young, Oregon OSHA. Editing and.. to handfeed and manipulate the stock.. horizontal) and vertical boring mills.

A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, theres a Haas to do the work.

Water Wheel Design. The water wheel design used most commonly in Great Britain and the United States was the vertical wheel rotating about a horizontal axle. In the Scottish highlands and parts of southern Europe mills often used a horizontal wheel (with a vertical axle).

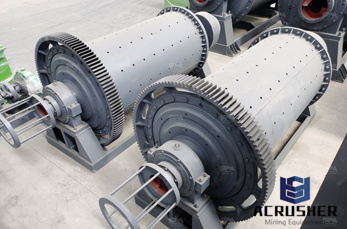

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

WhatsApp)

WhatsApp)