: grinding balls

4mm 46 Grit Round Ball Shape Diamond Grinding Head Drill Bits Rotary Tools for Internal Grinding Carbide in Ceramic, Glass, Alloy 3MM Shank 20Pcs out of 5 stars 13 9 . 99

WhatsApp)

WhatsApp)

4mm 46 Grit Round Ball Shape Diamond Grinding Head Drill Bits Rotary Tools for Internal Grinding Carbide in Ceramic, Glass, Alloy 3MM Shank 20Pcs out of 5 stars 13 9 . 99

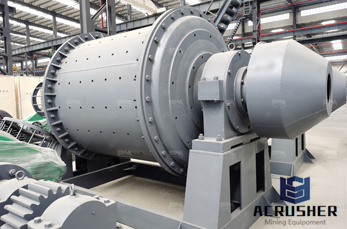

Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

ball mills have four grinding stations arranged on the quot;Sun Wheelquot; of the planetary ball mill. When the Sun Wheel rotates, the grinding balls inside the jars are subject to superimposed rotational movements, known as Coriolis Forces. The difference in speeds between the grinding balls and

Get the best deals for laboratory ball mill at We have a great online selection at the lowest prices with Fast amp; Free shipping on many items!

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mill 3/4 inch Chrome Plated Steel grinding media X 50 pcs Large 3/4quot; diameter, heavy chrome plated steel ball bearings. Use in place of lead balls where conta..

Get the best deals for ball mill balls at We have a great online selection at the lowest prices with Fast amp; Free shipping on many items!

6451 TransCanada Hwy Savona, BC V0K 2J0

In ceramics, ball mills are used to grind down materials into very fine particles. Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside them. During milling, the porcelain balls pulverized the

Ceramic Ball mill [ Capacity ]: t/h [ Applicable Material ]: Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

Ball mills of greater length are termed tube mills, and when hard pebbles rather than steel balls are used for the grinding media, the mills are known as pebble mills. In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 um.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

1,582 ceramic ball mill products are offered for sale by suppliers on, of which ceramics accounts for 41%, mine mill accounts for 34%, and grinding equipment accounts for 8%. A wide variety of ceramic ball mill options are available to you, such as ball mill.

3 lb capacity media ball mill Perfect size for the small hobbyist to mill black powder rocket pr 7499 heavy chrome plated Steel Ball Bearings Use in place of Lead balls where contact wit 2495 Add to Cart Add to Wish List Qty 20 1316 and Qty 20 12 Alumina ceramic cylinders for grinding Perfect for the 3Lb barrel oWe are a professional mining machinery manufacturer, the main equipment

WhatsApp)

WhatsApp)