Ball mill|Flotation machine|Magnetic separator|Spiral

Fote Machinery is major in producing ball mill,flotation machine,magnetic separator,spiral classifier,magnetic separation process,flotation separation process and other mining :market:+

WhatsApp)

WhatsApp)

Fote Machinery is major in producing ball mill,flotation machine,magnetic separator,spiral classifier,magnetic separation process,flotation separation process and other mining :market:+

Although conical mill design is a simple and elegant solution the physical process of separation and breakage of material in the mill is complex the challenge is to come up with the most efficient set of design and operating parameters of the mill to achi,Function Ball Mill In Separation Process.

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

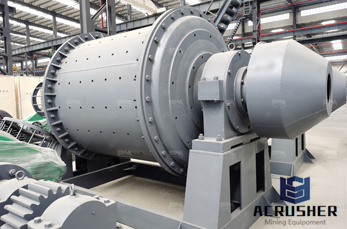

Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles with quality workmanship and materials used in the construction of the component parts. Your Ball Mill reflects years of advancement in grinding principles, materials, and

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Purpose The article reports a wet milling process, where the planetary ball mill was combined with pearl milling technology to reach nanosize range of meloxicam (Mel; 100500 nm).

ball mill for gold seperation process. Ball mills autogenous mills and semiautogenous mills from Thys senKrupp Polysius with diameters tion all around the world grinding copper ore iron ore ore iron ore and other mineral the mill inlet and outlet can be designed to suit the process technological

#0183;#32;During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig. chemical reaction on the other hand can consist of say reactant A forming intermediate product B then proceeding to final product C or a competing reactant A to final product D can also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

#0183;#32;15 BALL MILL The mill which is partially filled with balls of steel or pebbles is called ball mill. It is also called jar mills. Basis: This will works on the principle of impact and attrition. Construction: The ball mill consists of a cylindrical container.

gravity separation ball mill. gravity separation an overview sciencedirect topics gravity separation relies on the differences in density of minerals to provide efficient.. primary grinding of +1 mm screen oversized material in the ball mill in a...

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed

WhatsApp)

WhatsApp)